Learn an in-depth understanding of efficient solutions to oil well degassing challenges.

I. What is an anti-gas sucker rod pump?

An anti-gas sucker rod pump is a type of pumping equipment specifically designed to address high gas content in well fluids. It is an improved version of the sucker rod pump. Its unique structural design and degassing mechanism effectively prevent gas from entering the pump body, resolving the dddhhhgas lockdddhhh or dddhhhgas capdddhhh issues associated with conventional sucker rod pumps and improving oil recovery efficiency.

II. Development history and technological evolution:

In the mid-to-late stages of oil reservoir development, bottomhole pressure decreases and gas content increases. Conventional sucker rod pumps are prone to degassing and gas injection, seriously impacting production. To address this, anti-gas pump technology has gradually emerged since the 1980s.

The technological development process is summarized as follows:

| Decade | Technological Advances |

| 1980s | The first generation of mechanical anti-gas valve pumps was introduced, utilizing a bypass channel for exhaust. |

| 1990s | Multi-valve structures emerged, improving exhaust efficiency. |

| 2000s | Annular valve structures, top-fill valve exhaust, and float exhaust designs emerged. |

| 2010s | Combined with intelligent monitoring and dynamic simulation technologies, these technologies enable precise adaptation to well conditions. |

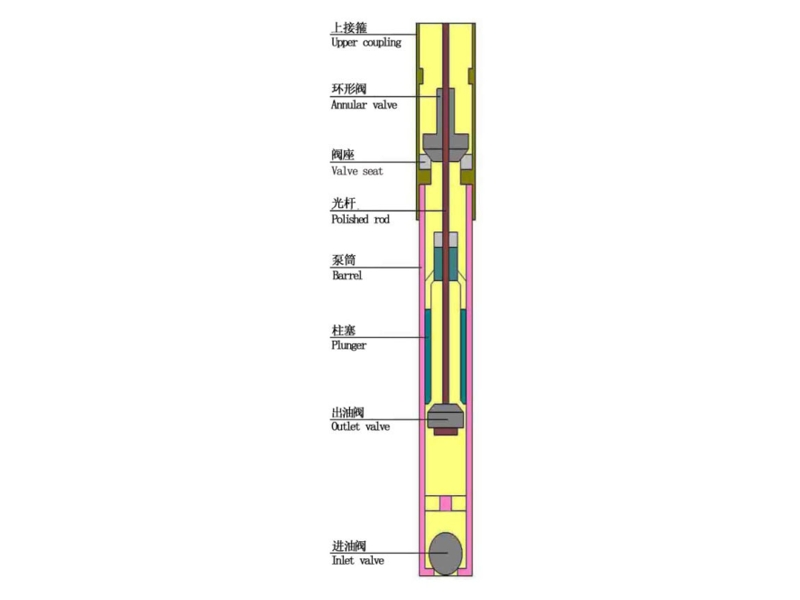

III. Anti-gas sucker rod pump structure (see figure below)

An anti-gas sucker rod pump is similar in structure to a conventional sucker rod pump, but features an exhaust device or structural optimization at the pump's top end to block or separate free gas from entering the pump body. Typical components are as follows:

| Component Names | Functional Description |

| Upper Coupling | Connects the sucker rod to the pump body |

| Annular Valve | Key airtight structure, venting gas while retaining liquid |

| Valve Seat | Supports the valve body, ensuring tightness |

| Polished Rod | Drives the pump plunger with up-and-down reciprocating motion |

| Barrel | Contains the main cavity for the plunger |

| Plunger | Core component for reciprocating suction and discharge of liquid |

| Outlet Valve | Controls upward flow of liquid |

| Inlet Valve | Controls the flow of liquid into the pump barrel |

IV. Anti-gas principle and working mechanism:

The dddhhhGas Lockdddhhh Problem of Conventional Oilfield Pumps

When the well fluid contains a large amount of free gas, the pump draws in gas instead of liquid at the end of the suction stroke. This prevents the liquid from effectively entering the plunger cavity, resulting in a dddhhhgas lockdddhhh or dddhhhempty pumping.dddhhh

Anti-gas sucker rod pump working mechanism:

Upstroke (Suction)

The plunger moves upward, the inlet valve opens, and liquid enters the pump barrel.

Simultaneously, gas is discharged through the annular valve, preventing it from entering the plunger cavity.

Downstroke (Discharge)

The plunger moves downward, compressing the liquid, opening the outlet valve and pumping liquid to the surface.

Gas continues to discharge upward and does not enter the pump cavity.

V. Common types and applicable scenarios:

| Type | Features | Application Scenarios |

| Annular airtight pump | Economical and practical with a ring-shaped valve structure | Low-medium production wells with moderate gas-liquid ratios |

| Separate chamber airtight pump | Increased internal compartments enhance gas-liquid separation | Wells with large fluctuations in gas content |

| Dual valve float pump | Automatically controlled gas-liquid passage with floats | High-gas content wells and deep wells |

| Internal exhaust pump | Built-in exhaust diversion system | Special wellbore space constraints |

VI. Maintenance Recommendations:

Regularly check the plunger and valve seat for wear.

Observe the pump for any dddhhhdry strokedddhhh at the end of the stroke.

Clean the valve body and annular cavity for wax or scale buildup.

VII. Common faults and troubleshooting suggestions:

| Symptoms | Possible causes | Troubleshooting methods |

| The pumping unit continues to pump dry | Failure of the annular valve, excessive gas content | Check valve seals and adjust exhaust mechanism |

| The gas content suddenly increases | Downhole water seal failure, gas cone formation | Measure pressure to analyze downhole fluid conditions |

| Liquid production decreases, but power remains constant | Pump stuck, valve clogged | Pull out the pump to check for wear on the pump barrel and plunger |

FAQ:

Q1: How much more expensive is an anti-gas sucker rod pump than a regular oil well pump?

A: Generally 15%-30% more expensive.

Q2: Is it suitable for horizontal wells?

A: It must be used with a downhole gas separator for optimal degassing.

Q3: Is it suitable for wells with high sand content?

A: We recommend a wear-resistant pump barrel and sand-proof plunger.

Q4: Is there a limit on installation depth?

A: It depends on the pump model, but generally recommended is no more than 3,500 meters.