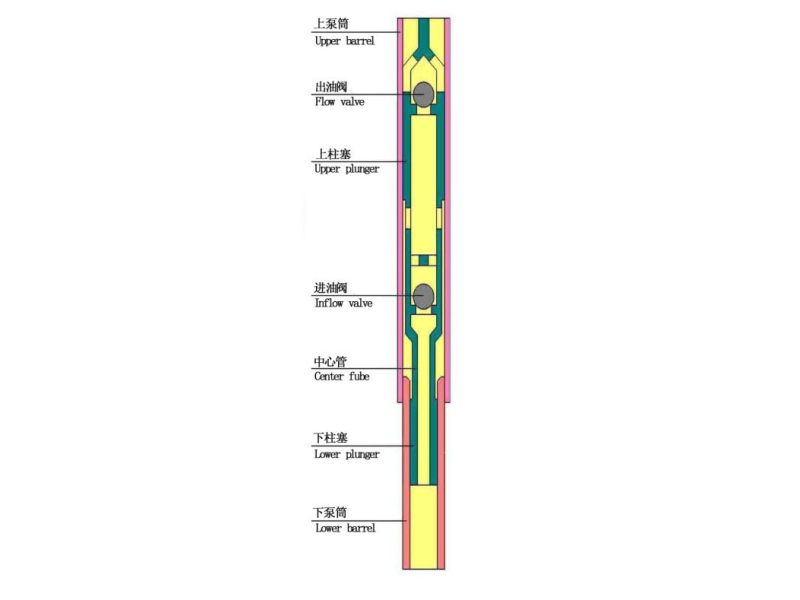

Hydraulic feedback sucker rod pump:

1. Working principle of hydraulic feedback sucker rod pump:

Hydraulic feedback sucker rod pump is composed of two pumps with different pump diameters connected in series, and the center tube connects the upper and lower plungers into one. During the upstroke, the plunger assembly moves upward, the volume of the annular cavity between the upper plunger and the lower pump barrel increases, the pressure decreases, the oil inlet valve opens, and the oil outlet valve closes under the pressure of the liquid column in the oil pipe, and the well fluid enters the annular cavity through the oil inlet/discharge joint. During the downstroke, the plunger assembly moves downward, the volume of the annular cavity between the upper plunger and the lower pump barrel decreases, the pressure increases, and the well fluid in the annular cavity closes the oil inlet valve through the oil inlet/discharge joint, the oil outlet valve opens, and is discharged into the oil pipe through the inner hole channel of the upper plunger. At this time, since the oil inlet valve is closed, the pressure of the liquid column in the oil pipe is applied to the lower plunger through the oil inlet valve (hydraulic feedback force), forcing the plunger to overcome the friction resistance of the heavy oil and move downward.

2. Structural features of hydraulic feedback sucker rod pump

⑴Hydraulic Feedback Sucker Rod Pump consists of two pump barrels and two plungers. It generates a large feedback force during the downstroke, greatly reducing the downward resistance of the rod column and improving the force condition of the sucker rod;

⑵The valve cover is a four-slot streamlined structure with a large flow area and small flow resistance, which improves the filling coefficient of the pump; it is suitable for crude oil production with a viscosity below 2000mPa.s.

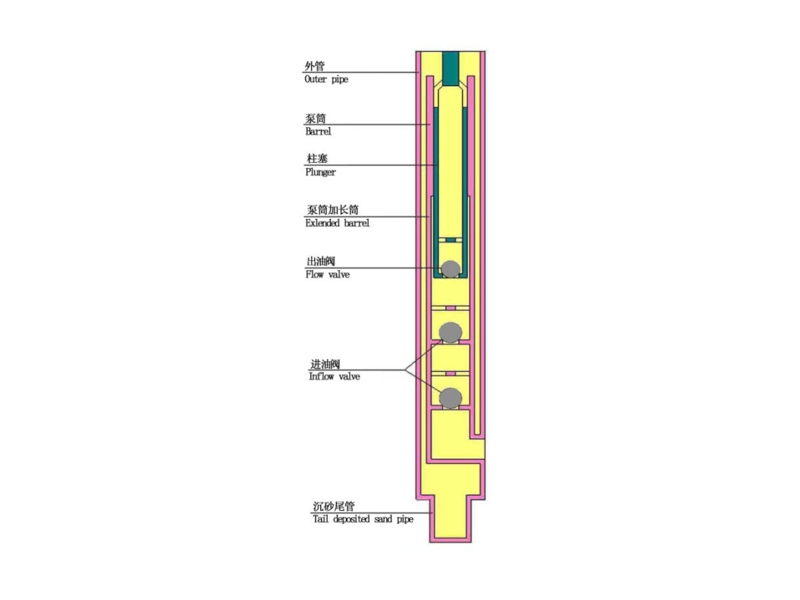

Long plunger sand control pump:

1. Working principle of long plunger sand control pump:

The pumping process of long plunger sand control pump is similar to that of ordinary oil pump. During the pumping process, the liquid in the well enters the pump through the lateral oil inlet hole of the bridge oil inlet valve assembly and is discharged to the pump by the plunger.

2. Structural features of long plunger sand control pump:

⑴Since the upper movable valve cover of the long plunger sand control pump is always exposed outside the pump barrel, the oil flow section is not limited by the inner diameter of the pump barrel, so the oil discharge resistance is smaller than that of conventional pumps. The plunger has a smaller downward resistance and a higher pump efficiency, so it is also suitable for pumping heavy oil.

⑵ The plunger keeps the pump barrel sealed, so that the sand in the pipe is not easy to deposit between the pump barrel and the plunger.

⑶ Long plunger sand control pump has an independent sand settling channel to prevent the settled sand from being pumped out again.

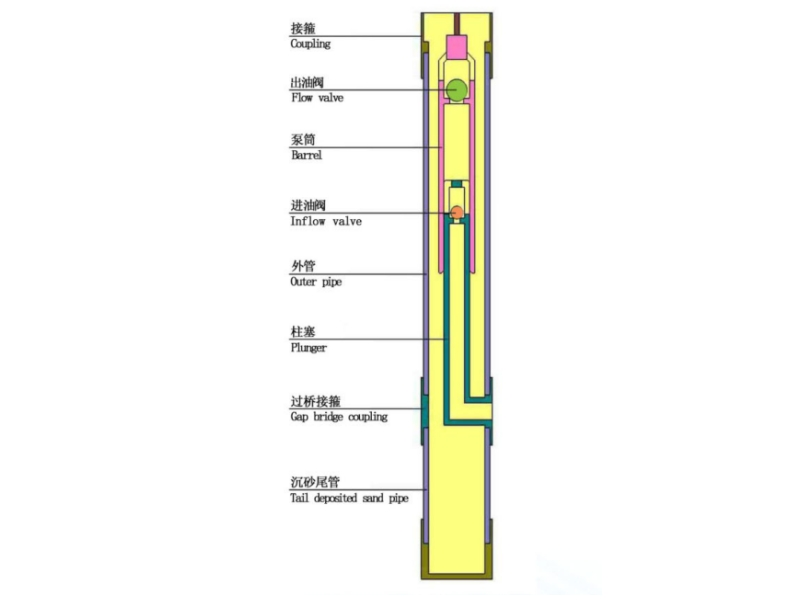

Movable barrel sand control oil well pump:

1. Working principle of movable barrel sand control oil well pump:

During the upward stroke of movable barrel sand control oil well pump, the pump rod drives the pump barrel upward, the oil outlet valve is closed, the space in the pump barrel cavity increases, the pressure drops, and the liquid in the well opens the oil inlet valve and enters the pump cavity. During the downward stroke of movable barrel sand control oil well pump, the pump barrel moves downward, the pressure in the pump increases, the oil outlet valve opens, the oil inlet valve closes, and the liquid in the pump is discharged into the oil pipe.

2. Structural features of movable barrel sand control oil well pump:

⑴ The pump barrel moves up and down, and the plunger is fixed to the pipe by an extension tube.

⑵ The oil outlet valve is always above the pump barrel. When pumping stops, sand burial and sand jamming are avoided. Sand deposited in the annular space of the pump barrel and the outer tube can be prevented from being pumped out again.

⑶ The plunger extension tube is a slender rod with poor stability. Therefore, the movable barrel sand control oil well pump is not suitable for long-stroke pumps and heavy oil wells;

⑷ The pump barrel moves up and down in the oil pipe, and the movement space is limited. The displacement of the pump is small; because the oil inlet valve is smaller than the oil outlet valve, it has an impedance effect on the liquid flow.

Double-acting oil well pump:

1. Working principle of double-acting oil well pump:

The lower fixed valve of the double-acting oil well pump opens during the upstroke. At the same time, the volume of the upper chamber decreases, the pressure increases, the upper fixed valve closes, the lower movable valve closes, and the oil flow in the upper chamber opens the upper movable valve and is discharged from the ground through the upper plunger.

During the downstroke of the double-acting oil pump, the lower fixed valve is closed, the lower movable valve is opened, and the upper movable valve is closed, and the crude oil enters the oil pipe through the lower plunger and the upper plunger. At the same time, the volume of the upper chamber increases, the pressure decreases, the upper fixed valve opens, and the crude oil enters the annular space between the oil pipe and the casing to pump oil.

2. Structural features of double-acting oil pumps:

⑴ One reciprocating stroke can complete the process of pumping and discharging oil twice. The double-acting oil pump has a higher liquid production than the oil pump with the same pump diameter and working parameters.

⑵ Because the downward resistance of the rod column is large during the downstroke, it is not suitable for use in oil wells with excessive crude oil viscosity and severe sanding, and the pumping rod column is easy to break off.

Inclined well pump:

1. Working principle of inclined well pump:

The inclined well pump is composed of a pump barrel, a plunger, a rotating movable joint, a floating valve, a fixed valve, an outer pipe, a rotating pipe plug, a pump barrel coupling and other components.

Upstroke: The sucker rod drives the plunger upward, and the floating valve is closed. At this time, the volume of the working chamber increases, forming a low-pressure chamber, the fixed valve opens, and oil enters the pump chamber.

Downstroke: The plunger moves downward under the drive of the rod column, the volume of the working chamber decreases, forming a high-pressure chamber, the floating valve opens, and the fixed valve closes at the same time, and oil flows out of the pump chamber.

Compared with conventional oil pumps, the lower part of the plunger of the inclined well pump is increased with a rotating pipe plug. During the pumping process, the component force generated by the impact force of the well fluid drives the plunger to rotate. The upper part of the plunger and the sucker rod are connected with a flexible joint to realize the free rotation of the plunger.

2. Structural features of inclined well pumps

Inclined well pumps are mainly used in inclined wells, directional wells, and side drilling wells, and can be used in oil wells with an inclination angle of less than 65°.

The inclined well pump adopts a streamlined valve cover with a guide rib structure and adds a plunger rotator, so that the plunger rotates automatically relative to the pump barrel during the pumping process, reducing the eccentric wear between the plunger and the pump barrel.